WHO WE ARE

ABOUT HEWITT

Since its founding in 1991, HEWITT EQUIPAMENTOS has been a pioneer in the railway sector, establishing itself as a reference in both the national and international markets. Initially focused on commercial representation for foreign trade, the company evolved to become one of the leading Brazilian manufacturers of Track Switching Devices and their components, headquartered in Hortolândia, São Paulo.

Hewitt Equipamentos’ growth and prominence in the market are evidenced by the acquisition of COBRASMA technology, expanding its operations to include bogies, track switching devices, frogs, switch points, and bumpers. This strategy has allowed the company to diversify its portfolio and offer more comprehensive solutions to meet the demands of the railway sector.

Quality and customer service commitment are fundamental pillars of Hewitt Equipamentos. Over the years, the company has maintained a constant pursuit of excellence, significantly investing in the development of new technologies and the implementation of innovative solutions. This approach, focused on continuous improvement, has strengthened Hewitt’s position in the market, ensuring customer satisfaction and consolidating its reputation in the railway sector.

INDUSTRIAL PLANT

The Hewitt Factory features a built area of approximately 15,000 m², comprising three main warehouses, each playing a crucial role:

- In the first warehouse, we focus on the manufacturing of track switching devices, ensuring innovation and quality in every piece produced.

- The second warehouse houses our expertise in the creation of trucks, railway equipment, and high-performance steel products, reinforcing our commitment to excellence and durability.

- In the third warehouse, we concentrate our efforts on wheelsets, performing precision recovery and axle mounting, ensuring the reliability and efficiency of every process.

In addition to the built area, Hewitt has an extensive 20,000 m² yard for strategic storage, enhancing its ability to meet market demands with agility and organization. This synergy between modern facilities and ample storage spaces reflects the company’s commitment to offering high-quality and efficient railway solutions in all aspects of production.

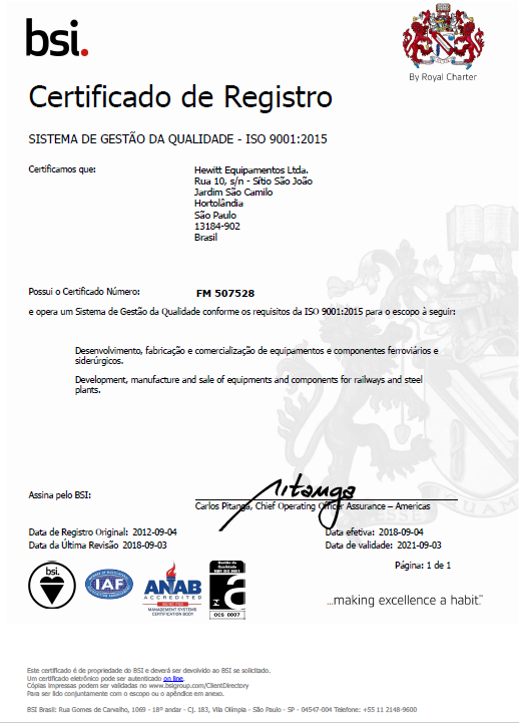

QUALITY

HEWITT is certified by the ISO 9001:2015 standard, operating in the Railway and Steel segments, considering the following points as a strategic part of its business:

- Transforming customer expectations into reality

- Being competitive to remain in the market

- Working as a team to always achieve the best results

- Seeking continuous improvement of Processes, Products, and Management Systems

OUR HISTORY

Founded in 1991, HEWITT EQUIPAMENTOS LTDA originated as a commercial representation focused on foreign trade.

In 1997, at the factory located in the city of Hortolândia, São Paulo, Hewitt began manufacturing Track Change Devices and their components, a segment in which it stood out, becoming one of the largest Brazilian producers. In the same year, with the acquisition of COBRASMA technology, it also started operating in the Special Steel Vehicles segment, such as torpedo cars for transporting liquid pig iron and transfer cars.

In 2004, it patented and started producing Sheet Metal Bogies for freight railway wagons. In the same year, it specialized in Wheelset Recovery Services for steel wagons, cargo, and passenger cars, riveting of railway bogies, and general bogie recovery.

In 2008, expanding its operations, Hewitt developed a project to manufacture Welded Sheet Metal Bogies for the Fortaleza Light Rail Vehicles (Metrofor).

In 2009, it began manufacturing Welded Sheet Metal Bogies for Passenger Cars destined for the Brasília Metro. It also added to its product line railway components such as Headstocks and Anchoring Supports for the passenger car segment. Shortly after, it manufactured welded sheet metal bogies for locomotives and passenger cars (Salvador Metro).

In 2018, it added the AMV product of Mobile Tip No. 12 and No. 20 to its catalog.